There are two ways that we test the tortuosity

- For more than 0.1mm( tortuosity ), we use a feeler, as shown below, the rod is placed at the level of the table, in the largest part of the gap thickness foot with 0.1,0.2,0.3mm …… go into, if the feeler can be through from the gap, means the tortuosity is bigger than the feeler thickness, for example, if request the tortuosity is less than 0.2mm, then the greatest gap of the rod with horizontal plane can not be stuffed 0.2mm thick feeler

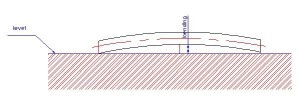

- Forless than 0.1mm (tortuosity) grinding rod, we use the optical projector test, placed the rod in a horizontal plane as shown in the figure, enlarge the aperture optical projection, and then measure the size of the maximum gap.

(3) The following form is a the our product test standards

| external diameter (D) | Limit deviation | roundness

(O) |

Unstraightness | surface roughness | |||||

| external diameter (D) | Length (L) | Length (L) | |||||||

| L<80 | 80≤L≤200 | L>200 | ≤0.15 | L<80 | 80≤L≤200 | L>200 | Ra0.8 or Sintered | ||

| D≤3.0 | +0.3

+0.1 |

+2.0

+0.1 |

+3.0

+0.1 |

+5.0

+0.1 |

≤0.2 | ≤0.3 | ≤0.4 | ||

| 3.0<D<10.0 | ≤0.1 | ≤0.2 | ≤0.3 | ||||||

| 10.0≤D≤16.0 | ≤0.1 | ≤0.1 | ≤0.2 | ||||||

Be the first to comment on "There are two ways that we test the tortuosity"