Step 1: Check accessories and packaging inspection, power on to test machine .

Step 2: Put into the grinding balls and materials, pay attention to the application of balls with large, medium and small sizes, the large ball are used for crushing the material and scattered small balls, small balls for mixing and grinding samples.

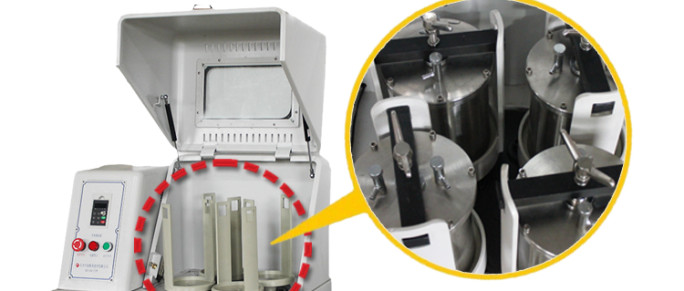

Step 3: Install grinding jars tightly to avoid spilling materials and , pay attention to the milling canned firm, avoid milling process from mill pot holder pot to prevent the material spilled, milling tank damaged.

The fourth step, standby power, after the equipment power, have open air switch, safety switch.

The fifth step, set the drive parameters.

The sixth step, abrasive, according to the material, the user requirements, after setting the function parameters of the inverter, tightly cover and start the run button to start the abrasive.

Seventh step, stop unloading tanks, materials After grinding, press the stop button, unplug it.

The eighth step, unloading, open the cover, loosen the hex nut with a wrench, removed the T-screw, pole, gaskets, remove the mill pot.

The ninth step, unloading, the tank material and milling balls poured into a small plugs, grinding balls and material separation with a plug and then plug once the material separation. Finally, the materials needed to pour the sample bag.

The tenth step, cleaning equipment, the mill pot and balls cleaned with a rag to wipe the device from the inside to the outside clean.

These are the planetary ball mill operating instructions and precautions outlined hope customers can follow the correct procedure, so as to enhance the effect of reducing planetary ball mill planetary ball mill failure.

Stay tuned for detailed product information company official website:www.industryequips.com, please contact:angela@metalcarbidepowder.com

Be the first to comment on "Planetary ball mill operating instructions"