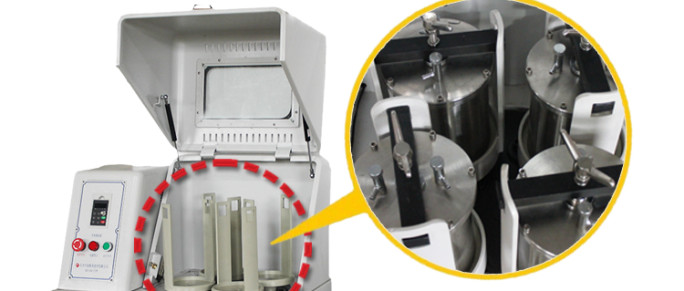

1, the loading planetary ball mill: loading a maximum volume (with the ball + sample + excipients) is a planetary ball milling tank volume 2/3, 1/3 as the remaining operating space. The strike has been installed, feed milling tank properly installed on the planetary ball mill, first with V-shaped handle clockwise pressed, note appropriate force, then lock the planetary ball mill with a flat handle, namely locking nut to prevent the screw loose accidents. Then cast safety cover. If you do not cover safety cover, the motor can not start.

2, the basic rules of a planetary ball mill grinding programmed:

(1) Get a planetary ball mill micron material optimum speed of 230 r / min or so, stirring and mixing common speed 180 r / min or so. It can be customized according to the experimental results.

(2) In order to obtain the best results, speed, milling time, with the ball, the sample size and number, add accessories and other parameters to choose the right.

(3) Speed: When the ball milling tank lid grind grooves, indicating speed is too high, it should reduce speed. High speed, efficiency is not necessarily high. At the start of the operation, the speed can be higher, played the role smashed sample operating period of time (usually no more than 2 min), speed can reduce the number, so that a higher milling efficiency. Milling efficiency depends on the level with the ball (large, small, more, less), with the right mix sample particle size, the speed, the milling time.

Stay tuned for detailed product information company official website: http://www.langfengmetallic.com/

interested to grind metal oxides & other rock (calcium carbonate, talc, etc) powder to make suspension concentrate. which machine can do up to 100 litres/day?

please advice and quote.

thanks, LIM JIT LING (Malaysia)