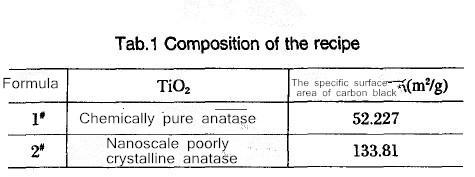

Experiments accurately weighed TiO2 and carbon black, mixed in a ball mill, ball milling with ethanol as medium milling time is lOh, after milling is completed, the sample was placed in a drying oven, and then the resulting mixed powder compression molding material, and then after drying, put in with color gel desiccant dryer for prepare.

Microwave heating is a multimode resonant cavity of a microwave oven. Frequency of the microwave source is 2.45GHz, the maximum output power of 10kW. After the sample was placed in a microwave oven, the first evacuation, in order to more accurately control N2 gas pressure, so first through Ar gas to 1.5atm, recanalization 0.05atm of N2 gas, and then the synthesis experiments at different temperatures. The temperature was measured by observing the hole insulating body, with precision optical pyrometer direct measurement of the temperature of the sample surface. Raised at a rate of 40 ℃ / min, reached the set temperature, followed by further incubation after lOmin, heating was stopped, the sample was cooled to room temperature with the furnace

Stay tuned for detailed product information company official website: http://www.langfengmetallic.com/

Be the first to comment on "Microwave synthesis of carbon titanium nitride experiments"