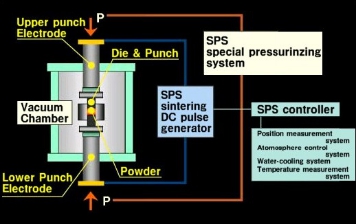

The SPS process is based on the electrical spark discharge phenomenon: a high energy, low voltage spark pulse current momentarily generates spark plasma at high localized temperatures, from several to ten thousand ℃ between the particles resulting in optimum thermal and electrolytic diffusion.

SPS sintering temperatures range from low to over 2000 ℃ which are 200 to 500 ℃ lower than with conventional sintering. Vaporization, melting and sintering are completed in short periods of approximately 5 to 20 minutes, including temperature rise and holding times.

Stay tuned for detailed product information company official website:www.industryequips.com, please contact:angela@metalcarbidepowder.com

Be the first to comment on "Physical activation sintering principle"