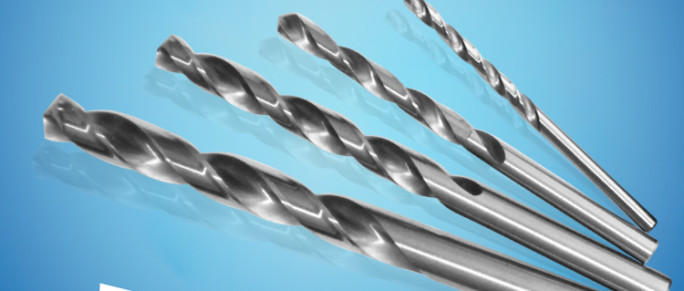

(1) The diameter of twist drill can be influenced by the aperture, spiral grooves make it be more detailed core drilling, drill rigidity is lower. There are only two edge band guidelines, hole’s axis are easily skew ; It’s difficult to make a centering because of chisel, axial resistance increases, drill is easy to swing. Therefore, drilled hole has the low accuracy.

(2) Both the rake face and flank face of the twist are curved, each point along the main cutting edge’s rake angle and bank angle varies, the rake angle of the chisel edge is -55 °. Cutting conditions are very poor; cutting along the cutting edge distribution is unreasonable, the lowest intensity has the maximum cutting tip, so it was badly worn. Thus, the hole machining accuracy is low.

(3) The main drill cutting edge participate cutting fully, each point on the cutting edge isn’t equal, it’s easy to form a spiral-shaped chip and difficult to remove chip . Therefore, chips and the hole wall always have friction and extrusion, often scratching the hole wall, and the surface roughness after machining is low.

Langfeng metallic material Ltd undertake the mission”benefiting all under the heaven”,creating value for customers,help employees grow and help more people progress and development is our firm goal.We specialize in military new materials of rocket systems , coating materials, carbide, cermet cutting tools and development of raw materials, high speed steel twist drill production and sales.Companies advocating green ideas, energy efficiency is the direction of the company, according to the needs of the company’s strategic development, the establishment of an industrial microwave division which is responsible for product development,and production sales.

Stay tuned for detailed product information company official website: http://www.langfengmetallic.com/

Be the first to comment on "Features of twist drill and its influence on cutting"