SPS process is a pressure assisted pulsed current sintering process utilizing ON-OFF DC pulse energizing. The repeated application of an ON-OFF DC pulse voltage and current between powder materials, the spark discharge point and the Joule heating point (local high temperature-state) are transferred and dispersed to the overall specimen and the homogeneously repeated phenomena and the effects during the ON stage on the specimen, result in efficient sintering at low power consumption.The SPS process concentrates high energy pulses at the point of intergranular bonding offering significant improvements over conventional hot-press and hot isostatic press sintering. Now, a look at the mechanism of neck formation during the SPS process.

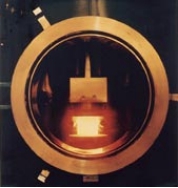

We have already explained under Principles that when spark discharge appears in the gap between the particles of a material, a local high temperature state of several to ten thousand ℃ momentarily occurs. This causes vaporization and the melting of the surfaces of the powder particles during the SPS process; constricted shapes or “necks” are formed around the contact area between the particles. These necks gradually develop and plastic transformation progresses during sintering, resulting in a sintered compact of over 99% density. Since only the surface temperature of the particles rises rapidly by self-heating, particle growth of the starting powder materials is controlled. Therefore, a precision sintered compact is manufactured in a shorter time. At the same time, bulk fabrication of particles with amorphous structure and nano-crystallization formation are now possible without changing their characteristics.

Stay tuned for detailed product information company official website: www.industryequips.com, please contact:angela@metalcarbidepowder.com

Be the first to comment on "Physical activation sintering Mechanism"