1) the major cutting edge is placed horizontally and parallel to the outer wheel.

2) Keep the angle between the drill center line and the outer surface of the wheel &Phi ).

3) drill head with his right hand, and added support for positioning the grinding pressure.

4) Left hand drill bit shank, right hand up and down swing assistance (Objective: After grinding angle).

5) left and right hands of the action must be well coordinated with.

6) sharpening, down, or under the can up up.

7) After grinding one side, flip the other side of 180 mill (grinding method ibid.).

Detection 8.3 after grinding drill

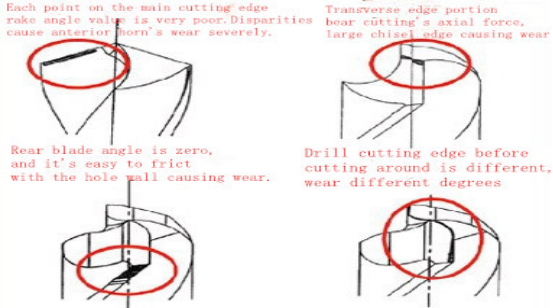

In the grinding process, the main cutting edge of the front corner, rear corner and chisel edge bevel is milled at the same time.

1) Drill after grinding method commonly used visual inspection. And visually, the drill upright, standing in front of two head, watching the blade, then the background should be clear.

2) because the two drill blades one after the other, will have observed parallax viewing two drill edge, often feel left edge (front edge) tall. Then the terrible rotate about an axis 180, so that repeated several times, if we look at the results, as evidenced by the symmetry.

3) ordinary twist drill grinding to prevent overheating and annealing cutting part should always be immersed in water to cool.

4) The angle of the general criteria of selection of the drill is 118 to 120 °

5) carbide drill can not be immersed in water to cool.

Stay tuned for detailed product information company official website: http://www.langfengmetallic.com/

Be the first to comment on "Method of drill bit wear and grinding"