The cemented carbide base consists of two parts: one is the hardened phase; the other is the bonded metal.

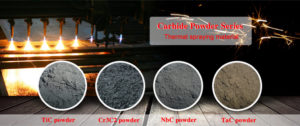

The hardening phase is the carbide of the transition metals in the periodic table of the elements, such as tungsten carbide, titanium carbide, and tantalum carbide. Their hardness is high, the melting point is above 2000°C, and some even exceed 4000°C. In addition, nitrides, borides, and silicides of transition metals have similar characteristics and can also act as hardened phases in cemented carbides. The presence of a hardened phase determines the extremely high hardness and wear resistance of the alloy.

For more information, please contact:

Changsha Langfeng Metallic Material Co., Ltd.

Tel: +86-731-86880480

Fax: +86-731-86880490

Sales department: sales@langfengmaterials.com

Add: No 98 Tianxiong Road, Furong Area, Changsha, Hunan pro ince, China.

Be the first to comment on "carbide powders in cemented carbide"